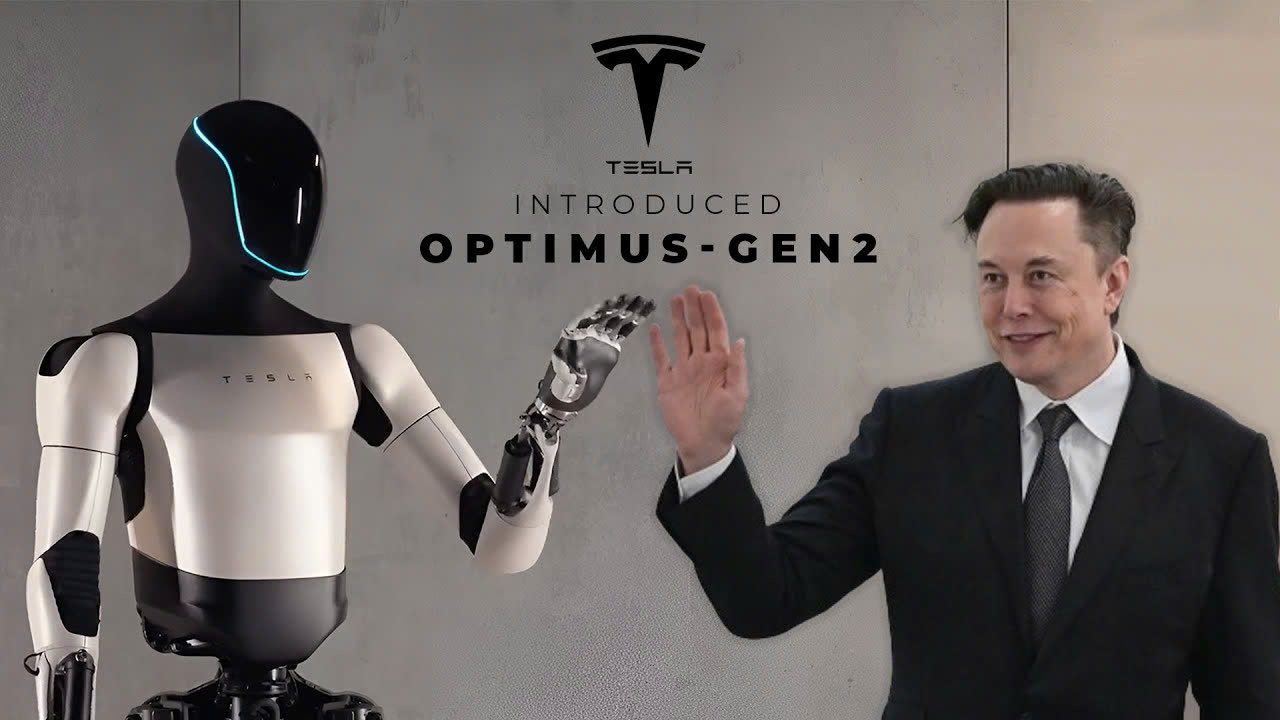

Tesla CEO Elon Musk Believes Humanoid Robot Optimus Will Generate Trillions in Profit, But It’s Been Called “Unrealistic.”

Announced by Tesla in 2021 and with the first prototype launched in 2022, Optimus stands 173 cm tall, weighs 57 kg, and is equipped with an information display screen. Elon Musk has frequently shared the progress of Optimus and envisioned a promising future for humanoid robots.

Musk and Tesla are currently facing numerous challenges in the electric vehicle business, with no new innovations in their vehicle models and declining sales. The robotaxi service is still being tested on a small scale. However, Musk continues to spend much of his time painting a bright future for both the robotaxi and Optimus robots, promising to make Tesla and investors extremely wealthy. According to Fast Company, the American billionaire seems to be chasing a “fantastical dream,” one that is unlikely to become a reality.

When Expectations Hit Real-World Barriers

In Musk’s vision, the future army of Optimus robots will carry batteries, pull spare parts, stack metal plates inside factories, or serve in households. They will take on monotonous, injury-prone jobs that no human would want to do.

Musk said that Optimus would begin operating on Tesla’s assembly lines by the end of this year. Next year, the robots will be used in warehouses and logistics centers across North America. Within five years, he promised to produce one million robots per year. Within a decade, there would be 100 million Optimus robots deployed widely. Last year, he even predicted that by 2040, 10 billion humanoid robots would be in operation globally.

“Optimus has the potential to generate over $10 trillion in revenue per year. It will be the largest product ever,” Musk told investors in April, repeating this statement during Tesla’s financial report on July 22.

In June 2024, he envisioned that Tesla could reach a $25 trillion market capitalization if Optimus became widely used — a figure that CNBC called “impractical and unrealistic.” Analysts suggest that the entire humanoid robot market could reach a value of $13–38 billion between 2030–2035, making Musk’s claim of $10 trillion in revenue mathematically impossible, at least within the next decade.

In reality, things are not progressing as the billionaire had hoped. According to experts, Optimus is moving much slower than its competitors, especially in China — which has a significant advantage in large-scale production supply chains.

Jeff Cardenas, CEO of Apptronik, the company behind the humanoid robot Apollo 1, commented that the humanoid robot industry is still “in the Macintosh era.” “It’s like the early stages of personal computers in the 1980s,” Cardenas said. “We’re still in the early stages, meaning Tesla still has a chance, but Musk’s $25 trillion market cap is impossible.”

A Series of Setbacks

According to Digitimes, the production of Optimus was delayed in mid-June due to overheating joints, soft wrists, and malfunctioning batteries after only a short period of operation. At the time, only about 1,000 robots had been shipped from the pilot production line in Fremont, California, with a cost of $60,000 per unit. Additionally, some videos showing the robot’s activities revealed that it moved at less than half the speed of a human.

AInvest cited two sources in the Optimus supply chain, saying that Tesla “has purchased enough parts” to produce 1,200 Optimus robots and has nearly produced 1,000 units — a “modest” number compared to Musk’s goal of producing 5,000–10,000 units this year. According to The Information, Tesla is reevaluating its suppliers due to issues with faulty parts, causing delays to continue.

One explanation for Optimus’ series of failures points to the reason Milan Kovac, the director of the Optimus program, suddenly left Tesla in June. The project is now being overseen by Ashok Elluswamy, Tesla’s Autopilot Director.

A major problem with Optimus involves rare earth materials required to produce magnets, which are essential to power the motors. Without these magnets, there’s no way to create a robot that moves at the speed and precision of a human.

Tesla has not disclosed how many magnets each Optimus robot requires, but according to analyst Luke Lango, the machine could use 3.6 kg of magnets since a humanoid robot typically needs more than 40 servo motors, and each motor requires almost 0.1 kg of magnets.

In April, Musk blamed Optimus’ production issues on the scarcity of rare earths, which are most abundantly found in China. With ongoing U.S.-China geopolitical tensions, this issue is expected to be difficult to resolve quickly.

“Designed to Fail?”

Even if all these challenges are overcome, Tesla still may not succeed with Optimus. According to Fast Company, Musk’s company is pursuing the most difficult factor in humanoid robot technology: lack of Lidar sensors.

Musk previously stated that Lidar “is for losers,” but using only regular cameras has proven insufficient to understand the surrounding environment. Tesla cars are not equipped with this sensor, increasing the risk of accidents. Statistics show that from 2019-2023, Tesla vehicles were involved in 736 accidents in the U.S., including 17 fatal ones, not including near-misses, according to Car&Driver. Robots without Lidar are predicted to face similar risks.